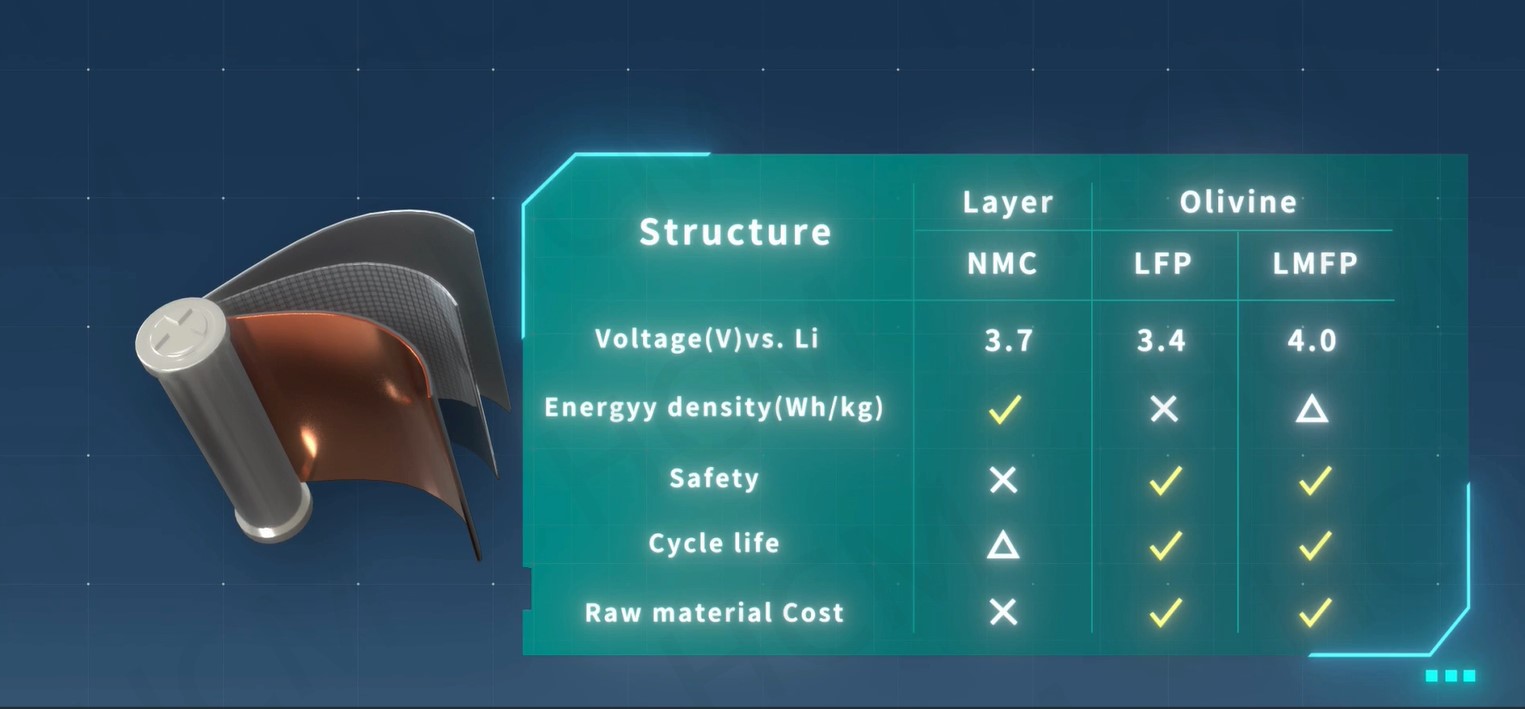

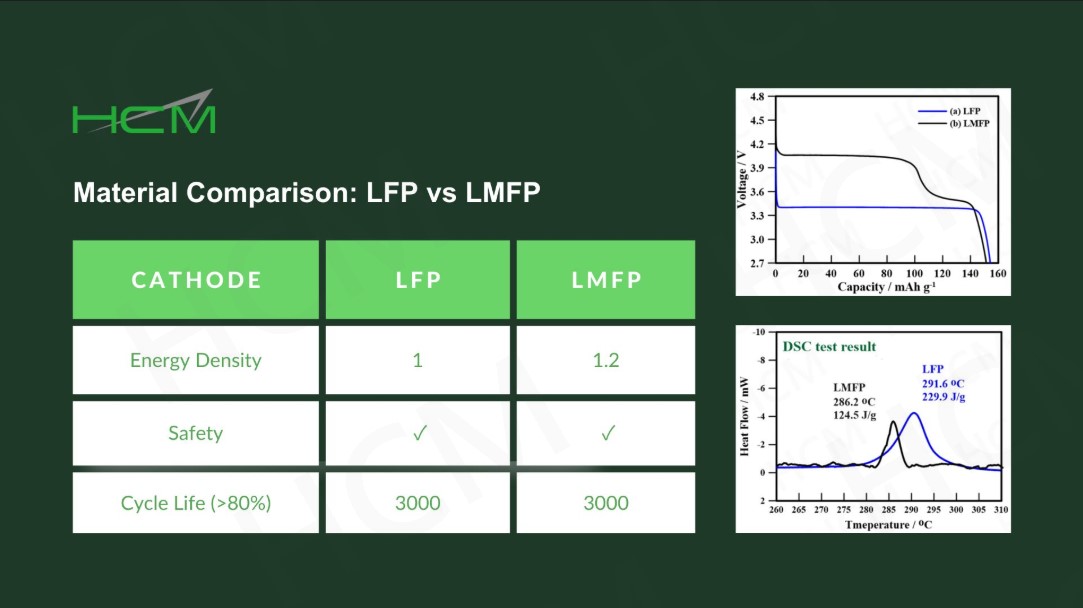

Energy Density

Article Source: GaogongIron Website http://www.gg-lb.com/asdisp2-65b095fb-27536-.html

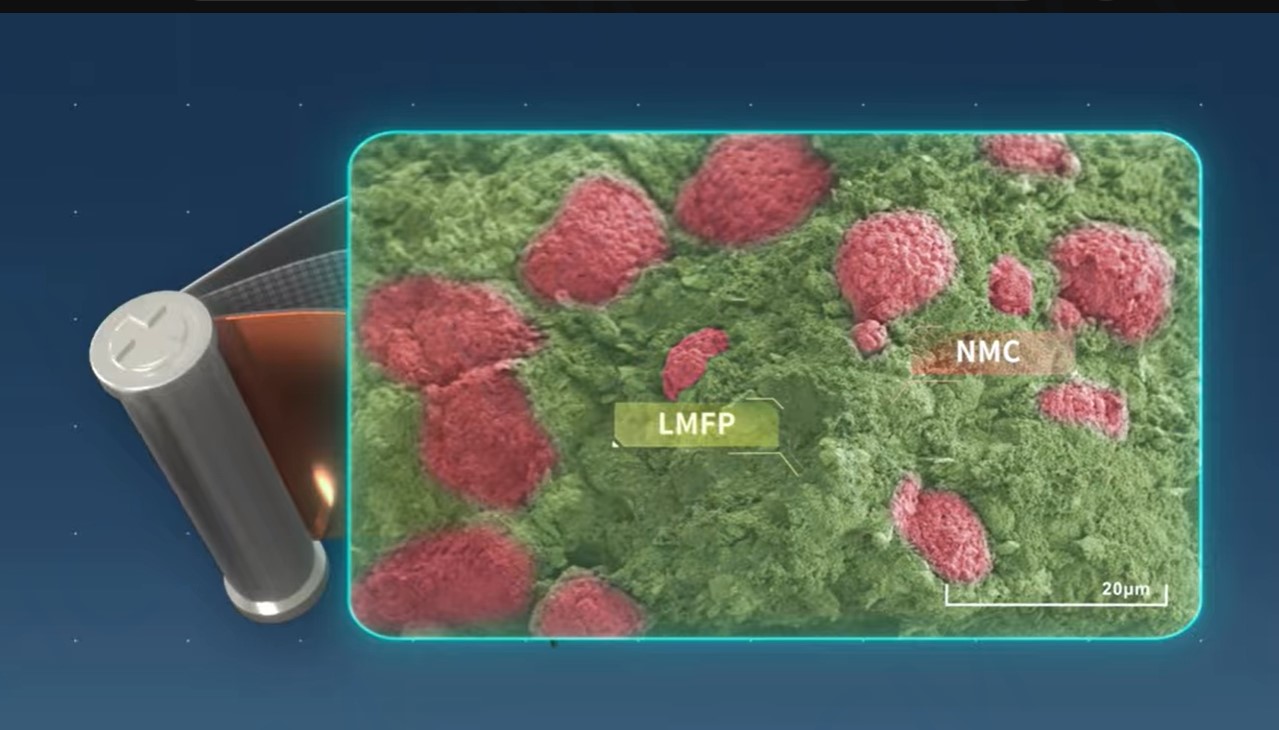

LMFP, a cathode material that was once considered to be the next generation power battery, has recently attracted attention from several battery manufacturers after a period of silence due to the problems of price, performance, and production difficulty.

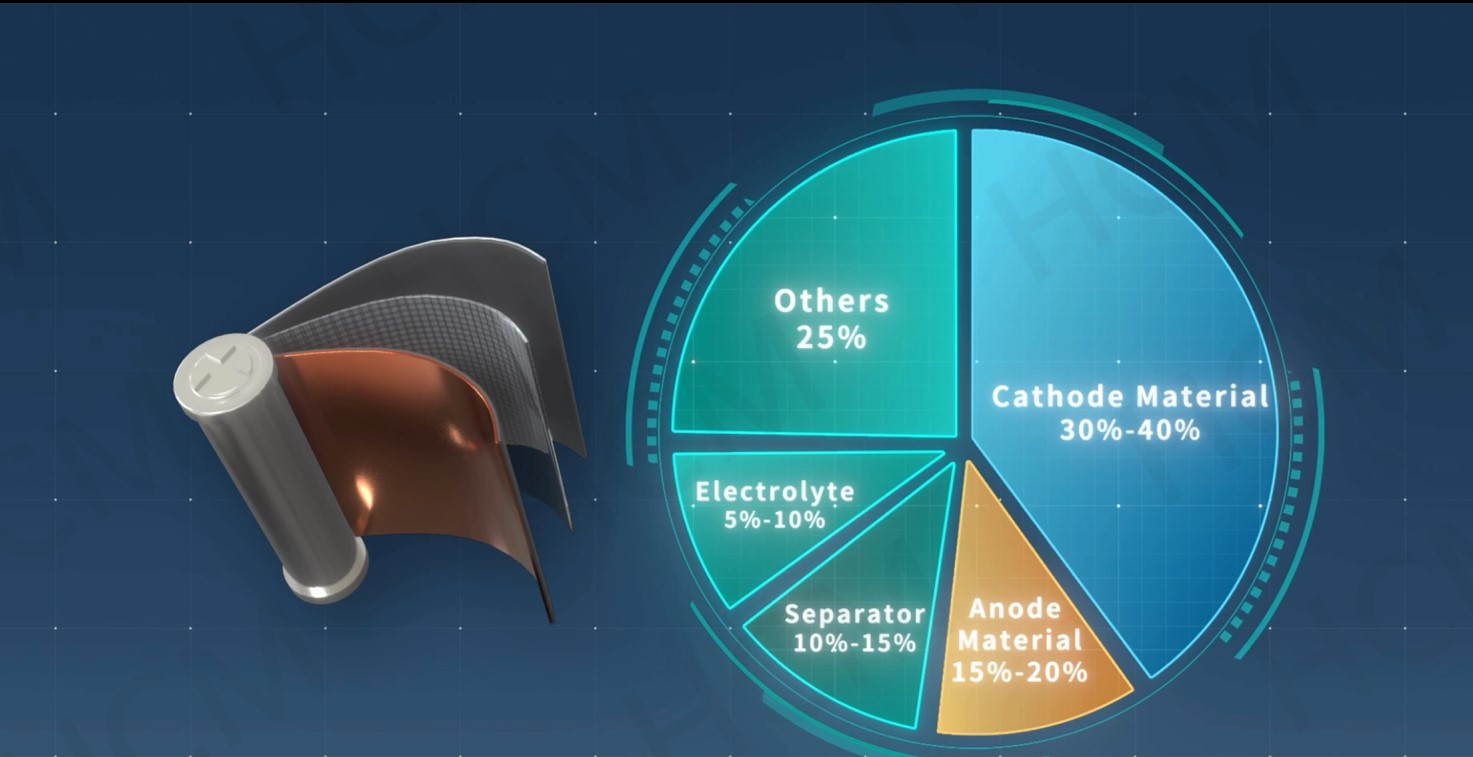

With the recent surge in the price of cobalt from USD28/kg (2016/10/17) to USD55.5/kg (2017/4/4), NMC (523) also increased from NT150 thousand to NT200 thousand per ton. The author believes that in the short and medium term, there is no reason for the cobalt price to fall. As demand increases and supply decreases, it is difficult to guarantee that the price of NMC will not rise again. Therefore, LMFP is relatively inexpensive, making NMC and LMFP mixture a key focus in the industry.

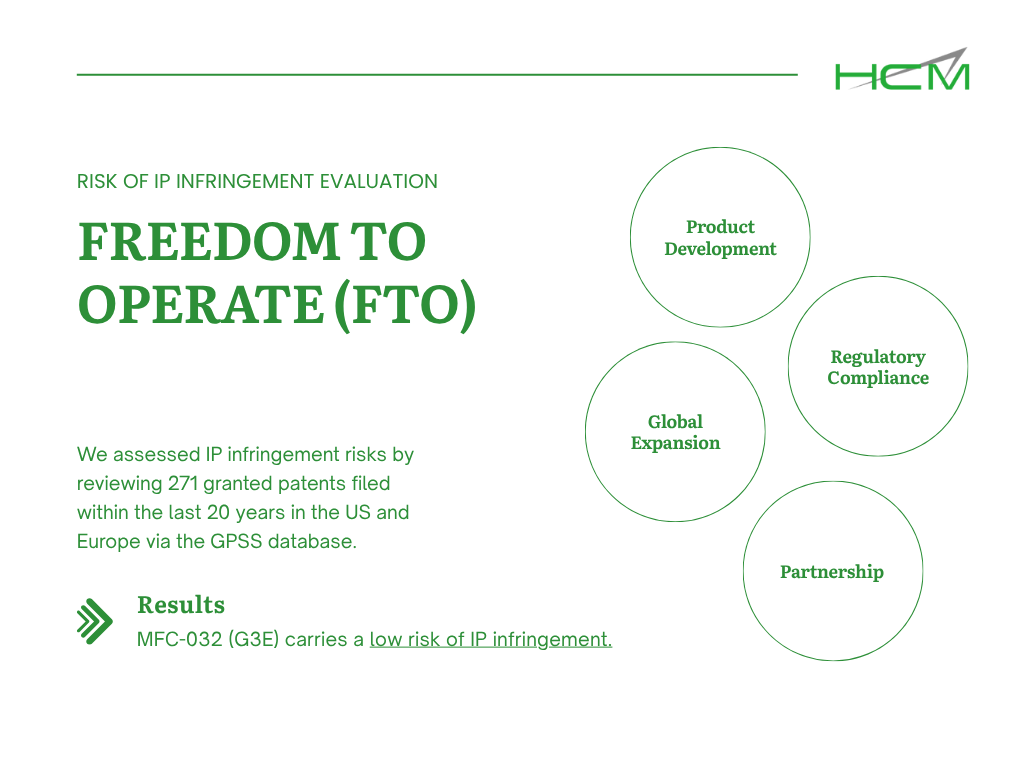

The Dow Chemical Company (exited the market two years ago), Sumitomo Osaka Cement and Phostech and some domestic cathode materials factories are all LMFP manufacturers.However, The Dow Chemical Company was the only one that can put LMFP into mass production. At that time, the manufacturer was Taiwan's HCM (formerHirose Tech Co., Ltd).At present, in terms of mass production standards, HCM has shipped nearly 100 tons, and the development of a new generation of LMFP will soon be completed.

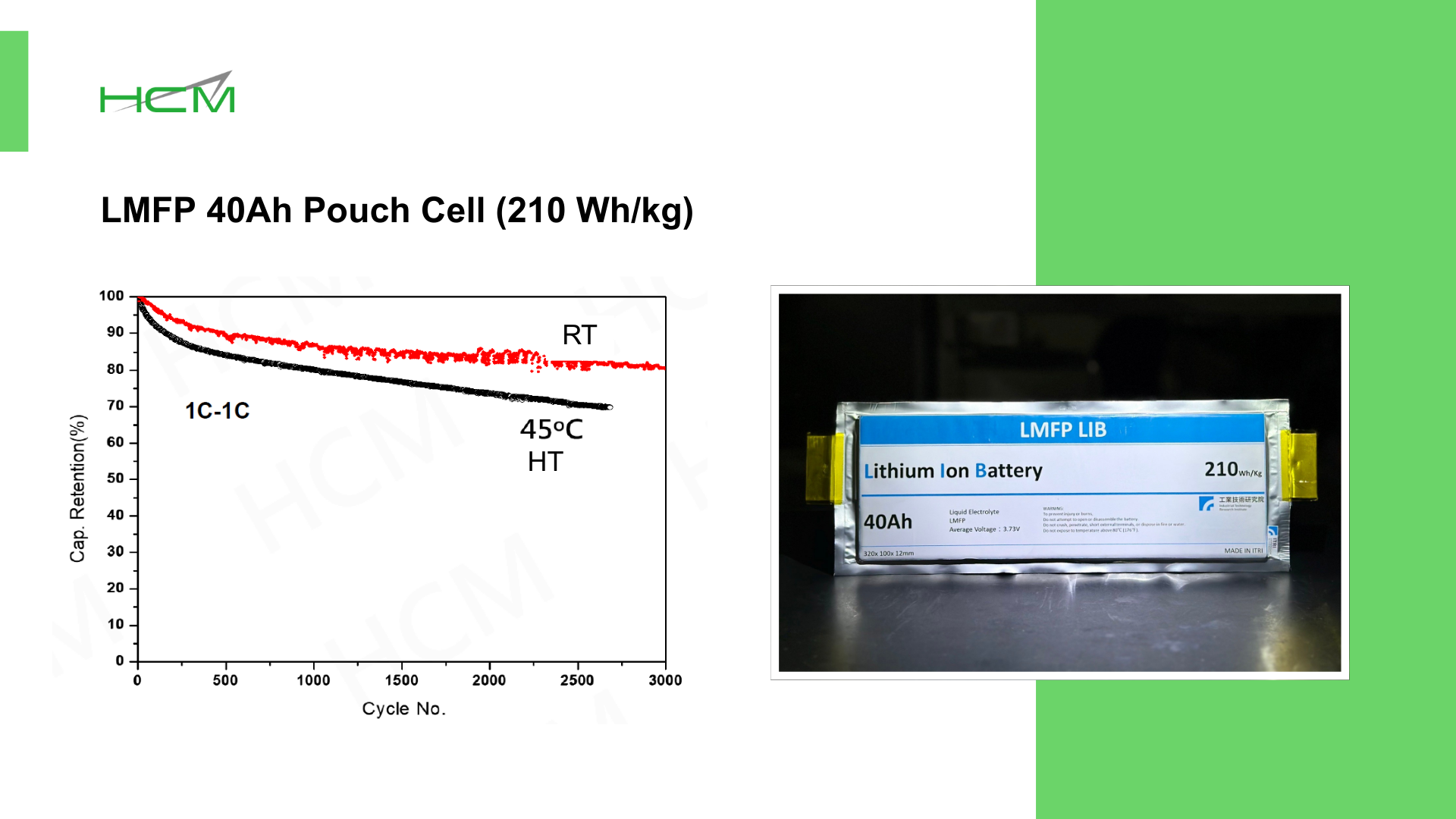

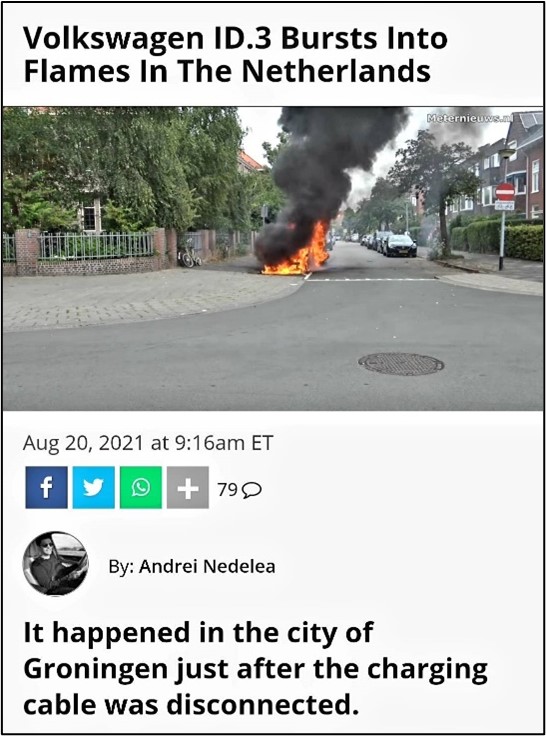

As to the application of cathode materials, NMC is used in automobiles and lithium iron is used in buses. However, NMC will inevitably moves towards a high energy density nickel NMC. High energy positive electrode often represents a high risk. It has been proven domestically and by foreign manufacturers such as Denso and China Aviation Lithium Battery Co., Ltd., that LMFP and NMC mixture can effectively solve the safety problem of NMC. With its full capacity, LFP batteries can achieve 150 wh/kg, which is very close to the theoretical value, so there is almost no room for further increase. However, the NMC(622) plus LMFP can easily achieve more than 200 wh/kg. Therefore, whether the application of lithium iron on buses can be stable is still uncertain.

The cathode material developed by the new-generation ISS (Idle Start-Stop System) is LMFP. At the 2015 and 2016 Battery Japan Conferences in Japan, Denso and Toshiba have published multiple reports that show the absolute advantages of LMFP replacing LMO applications on the ISS.

LMFP has the advantages of high voltage, high safety, and the ability of mixing with NMC. Moreover, the manufacturing costs are close to lithiumiron. If the performance is further improved (I believe it is only a matter of time), it will meet the requirements of electric vehicle manufacturers: safe and high energy density. The answer to whether LMFP can occupy a place in the rising battery industry seems to be clear.